The pulp and paper industry has long been a part of modern manufacturing, providing essential materials for countless paper products we rely on daily.

However, in a global marketplace, this industry faces significant challenges, including intense competition, rising costs, and the need for sustainable practices. To remain competitive and profitable, pulp and paper mills must embrace digital transformation by adopting advanced process automation control systems.

Traditional manufacturing methods in the pulp and paper industry are often inefficient, labor-intensive, and prone to inconsistencies. Manual processes and outdated equipment can lead to quality issues, excessive waste, and high energy consumption, all of which directly impact profit margins. Additionally, the pulp and paper industry is under increasing pressure to reduce its environmental footprint and comply with stringent regulations.

Advanced process automation control systems, such as those offered by Proconex, provide a solution to these challenges. By leveraging cutting-edge technologies, including real-time monitoring, data analytics, and intelligent control algorithms, these systems optimize every aspect of the manufacturing process. From raw material intake to finished product output, advanced automation ensures consistent quality, maximizes efficiency, and minimizes waste, ultimately driving profitability and sustainability.

Profit Margins in the Pulp and Paper Industry

The pulp and paper industry is a capital-intensive sector that requires large investments in manufacturing facilities, equipment, and raw materials. With high fixed costs and fluctuating market demands, maintaining healthy profit margins is crucial for the long-term sustainability and growth of companies operating in this industry.

Profit margins directly impact a company's ability to reinvest in operations, fund research and development initiatives, and stay competitive in the market. In the pulp and paper industry, even a small percentage increase in profit margins can translate into significant financial gains, given the large scale of operations and the volume of products manufactured.

Moreover, cost optimization is a constant priority for pulp and paper mills. The industry faces challenges such as rising energy costs, stringent environmental regulations, and the need for efficient resource utilization. By optimizing processes and reducing operational expenses, companies can enhance their profit margins, ensuring long-term profitability and competitiveness.

Achieving cost optimization requires a multifaceted approach, including the implementation of advanced technologies, streamlined production workflows, and effective resource management strategies. By embracing digital transformation and leveraging cutting-edge process automation control systems, pulp and paper mills can unlock significant cost savings while improving efficiency, quality, and sustainability.

Proconex: The Leading Provider of Advanced Process Automation Control Systems

Proconex is a renowned supplier of advanced process automation control systems tailored for the pulp and paper industry. With decades of experience and a deep understanding of the unique challenges faced by pulp and paper mills, Proconex has established itself as a trusted partner for companies seeking to optimize their operations and improve profitability.

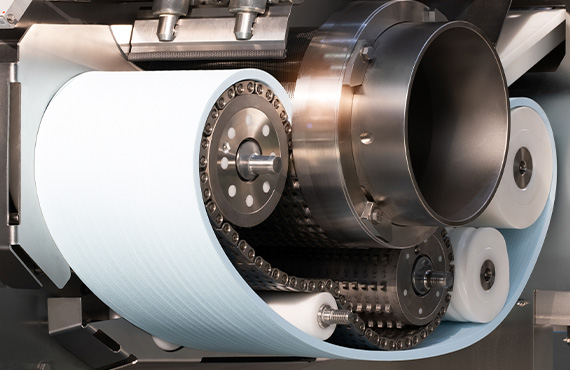

Proconex's cutting-edge automation solutions are designed to seamlessly integrate with existing infrastructure, providing a comprehensive and scalable platform for monitoring, controlling, and optimizing every aspect of the production process. From raw material handling to pulp processing, bleaching, power and recovery, and finishing operations, Proconex's systems offer unparalleled precision, efficiency, and reliability.

At the core of Proconex's offerings is a suite of advanced process control technologies that leverage real-time data, predictive analytics, and machine learning algorithms to ensure optimal performance and minimize downtime. These systems continuously monitor and adjust critical parameters, such as temperature, pressure, and flow rates, to maintain consistent product quality and reduce waste.

Optimize Processes with Advanced Automation Control Systems

Advanced automation control systems play a pivotal role in optimizing processes, reducing downtime, and improving efficiency in pulp and paper mills. These sophisticated systems integrate seamlessly with existing machinery and equipment, enabling real-time monitoring, data analysis, and precise control over every aspect of the production process.

One of the key advantages of advanced automation control systems is their ability to optimize processes through predictive maintenance. By continuously monitoring equipment performance and analyzing data, these systems can identify potential issues before they escalate into costly breakdowns. Predictive maintenance algorithms detect anomalies, wear patterns, and other indicators of impending failures, enabling proactive maintenance and minimizing unplanned downtime.

Moreover, advanced automation control systems facilitate process optimization by continuously monitoring and adjusting parameters such as temperature, pressure, flow rates, and chemical concentrations. This real-time control ensures that processes operate within optimal ranges, maximizing efficiency, reducing waste, and improving product quality consistency.

Another significant benefit of these systems is their ability to automate complex tasks and workflows. By integrating with various plant systems and equipment, advanced automation control systems can coordinate and synchronize operations, reducing manual intervention and minimizing the risk of human error. This automation not only enhances efficiency but also improves safety by limiting exposure to hazardous environments.

Furthermore, advanced automation control systems provide comprehensive data collection and analysis capabilities by using operations software. By capturing and analyzing data from various sources, these systems can identify bottlenecks, inefficiencies, and opportunities for improvement. This data-driven approach enables continuous process optimization, leading to increased productivity, reduced costs, and improved profitability.

Real-time Monitoring and Data Analytics

Advanced automation control systems from Proconex offer real-time monitoring and data analytics capabilities that provide pulp and paper mills with invaluable insights into their operations. By collecting and analyzing data from various sensors and equipment throughout the production process, these systems enable informed decision-making and proactive measures to optimize performance.

Real-time monitoring allows operators to identify potential issues or deviations from optimal parameters instantly. This early detection can prevent costly downtimes, quality issues, or inefficiencies, ultimately improving profitability. Automated alerts and notifications ensure that the right personnel are notified promptly, enabling swift corrective actions.

Further, the data analytics capabilities of Proconex's advanced automation control systems enable in-depth analysis of historical data, uncovering trends, patterns, and correlations that may not be immediately apparent. This data-driven approach empowers mills to continuously refine and optimize their processes, identify areas for improvement, and make informed decisions based on factual evidence rather than assumptions or guesswork.

By leveraging real-time monitoring and data analytics, pulp and paper mills can achieve higher levels of operational excellence, consistency, and efficiency, directly translating into improved profit margins and a competitive edge in the market.

Quality Control and Consistency

Advanced automation control systems play a crucial role in maintaining consistent product quality and reducing waste in the pulp and paper production process. These systems leverage sophisticated sensors, real-time data analysis, and precise control mechanisms to monitor and adjust various parameters throughout the manufacturing cycle.

One of the key advantages of these systems is their ability to continuously monitor and regulate critical variables such as pulp consistency, moisture content, fiber orientation, and chemical composition. By maintaining these variables within tightly defined ranges, the systems ensure that the final product meets stringent quality specifications, minimizing variations and defects.

In addition, advanced automation control systems can detect and respond to deviations or anomalies in real-time, allowing for immediate corrective actions. This proactive approach helps prevent the propagation of errors, reducing the risk of producing off-spec products and minimizing waste.

These systems also facilitate seamless integration with quality control laboratories, enabling rapid feedback loops and adjustments based on analytical data. By continuously optimizing the process parameters, advanced automation control systems help maintain consistent product quality while minimizing the need for manual interventions and rework.

Also, these systems can track and analyze historical data, enabling predictive maintenance and identifying potential issues before they manifest, further enhancing quality control and reducing downtime. Overall, the implementation of advanced automation control systems in pulp and paper mills significantly improves product consistency, reduces waste, and enhances operational efficiency, ultimately contributing to increased profitability.

Energy Efficiency and Sustainability

Advanced process automation control systems from Proconex play a crucial role in enhancing energy efficiency and promoting sustainability within pulp and paper mills. The pulp and paper industry is known for its significant energy consumption and environmental impact, making it imperative to adopt sustainable practices and optimize resource utilization.

Proconex's cutting-edge automation solutions enable real-time monitoring and precise control over various processes within the mill. By continuously analyzing data from multiple sources, these systems can identify areas of inefficiency and make necessary adjustments to minimize energy waste. Automated control over variables such as temperature, pressure, and flow rates ensures optimal operating conditions, reducing energy consumption while maintaining high production levels.

Moreover, advanced automation control systems facilitate the integration of renewable energy sources into the mill's operations. By seamlessly managing the distribution and utilization of energy from renewable sources like biomass, solar, or wind, these systems contribute to reducing the overall carbon footprint of the mill.

Additionally, Proconex's solutions help minimize waste and maximize resource recovery. Through precise process control and real-time data analysis, mills can optimize the use of raw materials, minimize waste generation, and identify opportunities for recycling and reusing byproducts. This not only reduces the environmental impact but also contributes to cost savings and improved profitability.

Proconex's commitment to sustainability extends beyond energy efficiency. Our automation systems also enable mills to monitor and control emissions, wastewater treatment, and other environmental aspects, ensuring compliance with regulatory standards and minimizing the ecological footprint of operations.

By embracing advanced process automation control systems from Proconex, pulp and paper mills can achieve a harmonious balance between profitability and environmental responsibility, positioning themselves as leaders in sustainable practices within the industry.

Implementation and Integration

Implementing and integrating advanced automation control systems in existing pulp and paper mills can be a complex process, but Proconex provides comprehensive support to ensure a smooth transition. Our team of experts works closely with mill operators to understand their specific requirements and challenges, tailoring the implementation process accordingly.

One of the key aspects of the implementation process is the seamless integration of the new automation control systems with the existing infrastructure and machinery. Proconex employs a modular approach, allowing for gradual integration and minimizing disruptions to ongoing operations. This approach ensures that the mill can continue to operate while the new systems are being installed and configured.

Proconex also offers extensive training and support services to ensure that mill personnel are fully equipped to operate and maintain the advanced automation control systems. Our training programs cover everything from basic operation to advanced troubleshooting and maintenance procedures, empowering mill staff to maximize the potential of the new systems.

Throughout the implementation and integration process, Proconex maintains open communication channels with mill operators, addressing any concerns or issues that may arise. Our commitment to customer satisfaction is evident in our responsive support and follow-up services, ensuring that the mills can fully leverage the capabilities of the advanced automation control systems and achieve their desired operational and financial goals.

Embrace Digital Transformation for Improved Profitability

The pulp and paper industry has traditionally been a capital-intensive and resource-heavy sector, facing numerous challenges in optimizing processes, reducing costs, and maintaining consistent quality. However, by embracing digital transformation and adopting advanced process automation control systems from Proconex, mills can unlock significant opportunities to improve profit margins and ensure long-term sustainability.

Proconex's cutting-edge solutions enable real-time monitoring, data analytics, and precise control over every aspect of the production process. This level of visibility and control translates into improved operational efficiency, reduced waste, and enhanced product quality, all of which contribute to increased profitability. Additionally, the advanced automation systems facilitate energy optimization, minimizing resource consumption and promoting sustainability efforts.

By partnering with Proconex, pulp and paper mills can future-proof their operations, staying ahead of the curve in an increasingly competitive and environmentally conscious market. The integration of advanced automation control systems not only streamlines processes but also empowers mills to make data-driven decisions, continuously improving and adapting to changing market demands.

Ultimately, the digital transformation facilitated by Proconex's solutions represents a strategic investment in the long-term success of pulp and paper mills. By embracing innovation and leveraging the power of advanced automation, mills can unlock new levels of profitability, efficiency, and sustainability, positioning themselves as industry leaders in the digital age.