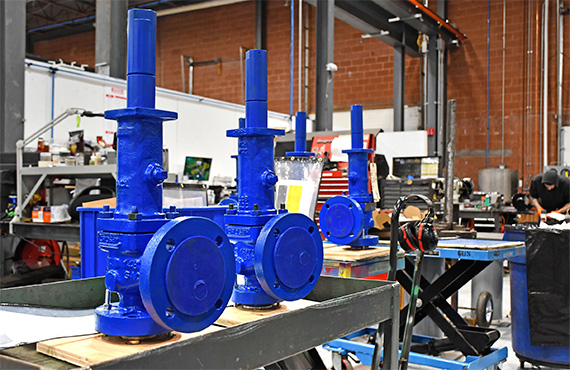

Pressure relief valves keep industrial systems safe and efficient. Pressure relief valves are the unsung heroes of industrial systems. They stand guard, ready to release excess pressure and protect your equipment from disaster.

But when they fail, the stakes climb fast; think damaged assets, halted production, or safety risks. Full-service pressure relief valve repair keeps those nightmares at bay. At Proconex, we offer expert repair for Crosby pressure relief valves and Anderson Greenwood pressure relief valves, ensuring your operations stay safe and efficient. Let’s dive into how this service prevents costly failures.

Why Pressure Relief Valve Repair Matters

Pressure relief valves don’t last forever. Wear, corrosion, or debris can clog their precision, turning a safety net into a liability. Regular repair isn’t just maintenance; it’s a lifeline. Skip it, and overpressure can wreck pipes, tanks, or worse; people. The Allied Market Research report projects the pressure relief valve market hitting $5.2 billion by 2030, growing 5 percent yearly. Why? Industries know reliable valves; and their upkeep—are non-negotiable for safety and uptime.

The Power of Full-Service Repair

Full-service pressure relief valve repair goes beyond quick fixes. It’s a deep dive; disassembly, cleaning, testing, and recalibration. Whether it’s a Crosby pressure relief valve on a steam line or an Anderson Greenwood model in a refinery, Proconex tackles every detail. Emerson, a valve powerhouse, backs this approach: https://www.emerson.com/en-us/automation/valves-actuators-regulators/pressure-relief-valves. A Processing Magazine study found repaired valves cut failure rates by 45 percent vs. neglected ones. That’s real protection.

How Repairs Prevent Failures

Here’s how full-service repair stops trouble cold:

- Spots Wear Early: Technicians catch cracks or seal decay before they fail. A water treatment plant repaired its water pressure reducing valve and dodged a $20,000 flood.

- Restores Precision: Recalibration ensures valves pop at the right pressure; no guesswork. Crosby valves thrive on this care.

- Clears Blockages: Debris jams valves shut. Cleaning keeps Anderson Greenwood models flowing right.

- Meets Standards: Repairs align with ASME or API codes, avoiding fines. The American Petroleum Institute says compliant valves slash regulatory issues by 30 percent.

- Extends Life: A Flow Control study pegs repaired valves lasting 25 percent longer than ignored ones.

A chemical plant skipped repair once; a valve stuck, the reactor overheated, $75,000 gone. Proconex’s full-service approach flips that script; fix it right and save big.

Key Steps in Full-Service Repair

Repair isn’t a slapdash job; it’s methodical. Start with inspection; check seats, springs, and bodies for wear. Next, disassemble and clean; blast away rust or buildup. Test performance; simulate pressure to confirm set points. Finally, reassemble and certify; ensure it’s ready for duty.

Real win: A power plant sent us a Crosby valve after a near-miss. Post-repair, it held steady through a pressure spike; zero damage. That’s the payoff of doing it right.

Industries that Rely on Repair

Proconex serves sectors where valve failure isn’t an option:

- Oil and Gas: Crosby pressure relief valves get full-service repair to keep flare stacks safe. Cross Company showcases this: https://www.crossco.com/process-solutions/pressure-relief-valves/.

- Chemical Manufacturing: Anderson Greenwood valves stay precise; vital for volatile processes.

- Power Generation: Steam systems lean on repaired valves for uninterrupted output.

- Water Systems: Repairing water pressure reducing valves prevents bursts; key for utilities.

- Refining: High-stakes lines need valves that won’t quit.

The Transparency Market Research report sees repair services growing 6 percent yearly through 2029; driven by aging systems needing TLC. Proconex keeps those systems humming.

Cost Savings from Quick Repair

Repair beats replacement every time. A new valve might run $5,000; repair costs a fraction. A Power Engineering analysis found full-service repair cuts lifecycle costs by 20–30 percent. Downtime shrinks too; fixed valves prevent stoppages that cost $10,000 a day in lost output, per Industrial Maintenance & Plant Operation. Plus, energy efficiency holds; leaky valves waste power.

A refinery client repaired Anderson Greenwood valves instead of buying new. Savings? $50,000 yearly, plus 35 percent less downtime. Proconex delivers that kind of ROI; practical fixes, big returns.

Why Skipping Repair Isn't an Option

Ignore repair, and chaos brews. Stuck valves miss pressure spikes; equipment buckles. A Plant Services survey ties 40 percent of system failures to neglected valves. Safety takes a hit too—overpressure risks explosions or leaks. A pulp mill learned this; unrepaired valve failed, $60,000 in repairs and a week offline. Full-service repair dodges that bullet; Proconex keeps your valves sharp.

Compliance matters here. Regulators don’t mess around; unmaintained valves mean penalties. A water utility faced $25,000 in fines for a faulty water pressure reducing valve. Repair keeps you legal and lean.

Crosby and Anderson Greenwood: Built to Last, Better with Repair

Crosby pressure relief valves handle fast pressure surges; spring-loaded and tough. Anderson Greenwood models excel in high-flow control; pilot-operated precision. Both shine brighter with full-service repair. A Modern Pumping Today report shows repaired Crosby valves hit 97 percent reliability in high-stress tests. Proconex trusts them because they endure; repair just seals the deal.

A gas plant repaired Crosby valves on compressors; no failures in four years. A water system fixed an Anderson Greenwood valve; leaks stopped, costs fell 20 percent. That’s why we back them.

Why Proconex for Valve Repair

Proconex brings 75+ years of know-how; since 1948, we’ve kept systems safe. We repair Crosby and Anderson Greenwood pressure relief valves for industries like:

- Oil and gas

- Chemical manufacturing

- Power generation

- Water systems

- Refining

Our 300+ pros don’t cut corners. Need a water pressure reducing valve fixed for a utility? We’ve got it. Crosby repair for a boiler? We’ll get it done right. We’re not just a shop; we’re your partner.

Keep Failures at Bay

Pressure relief valve repair isn’t optional; it’s essential. Full-service care catches issues, cuts costs, and locks in safety. Crosby and Anderson Greenwood valves, paired with Proconex expertise, keep your operation rock-solid. Want to stay ahead of failures? Explore our repair services at proconexdirect.com and keep your system running strong.