In industrial settings, steam is a vital energy source for processes like heating, power generation, and manufacturing.

However, managing steam effectively is key to maximizing efficiency and minimizing waste. Steam traps play a critical role in this by removing condensate (liquid water) and non-condensable gases from steam systems while retaining valuable live steam. This process enhances operational efficiency, reduces energy costs, and prevents equipment damage, making steam traps essential for cost-effective and sustainable operations.

How Does a Steam Trap Work?

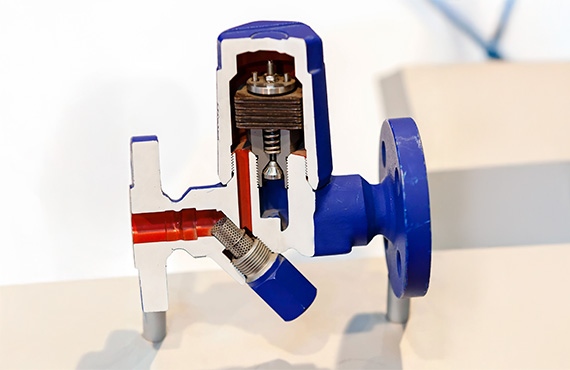

A steam trap is an automatic valve designed to discharge condensate and air from steam distribution systems without letting steam escape. The steam trap function relies on the physical differences between steam, condensate, and gases. Steam is a high-energy gas, while condensate is denser liquid water that forms as steam cools.

Here’s how it operates:

- Condensate Removal: As steam loses heat, it condenses into water, which can reduce system efficiency if left to accumulate. A steam trap valve opens to release this condensate, preventing water hammer, corrosion, or reduced heat transfer.

- Steam Retention: The trap closes when steam is present, preserving the energy-rich steam for its intended use.

- Air Venting: Non-condensable gases, like air, are also expelled, ensuring optimal heat transfer and system performance.

By maintaining this balance, steam traps keep systems running smoothly, reducing energy loss and operational downtime.

Types of Steam Traps

Steam traps come in various designs, each suited to specific applications based on how they detect and remove condensate. The main types include:

- Thermodynamic Traps: These use the dynamic properties of steam and condensate. A disc opens or closes based on pressure differences, making them durable and ideal for high-pressure systems like steam mains or tracing lines.

- Thermostatic Traps: Activated by temperature differences, these traps open when cooler condensate or air is present and close when hot steam arrives. They excel in air venting and are often used in heating systems.

- Mechanical Traps: These rely on the physical properties of condensate, using floats or inverted buckets that rise and fall with liquid levels to open or close the valve. They’re effective for high condensate loads in process equipment like heat exchangers.

Each type offers unique advantages, allowing industries to select the best steam trap for their specific needs, optimizing both efficiency and cost savings.

Yarway Steam Traps

Yarway steam traps, offered by Emerson and available through Proconex, are renowned for their reliability and versatility across industrial applications. Designed to minimize steam loss, they enhance energy efficiency while meeting diverse process demands. Key offerings include:

- Yarway F&T (Float & Thermostatic) Traps: Perfect for process applications with wide-ranging condensate loads, these traps combine mechanical float action with thermostatic air venting for superior performance.

- Yarway Thermostatic Traps: Known for excellent air-handling capabilities, they’re ideal for systems requiring precise temperature control and efficient gas removal.

- Yarway Thermodynamic Traps: Built for robust performance, these traps suit drip, tracer, and process applications, offering durability in high-pressure environments.

- Sanitary Steam Traps: Tailored for clean steam systems, these reduce downtime in industries like pharmaceuticals or food processing.

Proconex provides a selection of Yarway steam traps, backed by Emerson’s expertise, ensuring tailored solutions that boost efficiency and cut energy costs.

Efficiency and Cost Benefits

Steam traps improve efficiency by:

- Reducing Steam Loss: Properly functioning traps prevent steam from escaping, preserving energy for productive use.

- Preventing Downtime: By removing condensate and gases, they protect equipment from damage, minimizing costly repairs and interruptions.

- Optimizing Heat Transfer: Clear systems ensure consistent heat delivery, reducing the energy needed to maintain performance.

For example, a Gulf Coast chemical plant using wireless vibration sensors alongside steam traps halved downtime by catching pump issues early, showcasing how integrated solutions amplify savings. By lowering energy waste and maintenance costs, steam traps deliver a strong return on investment, making them indispensable for industrial operations aiming to stay competitive and sustainable.

Key Takaways

Steam traps are a cornerstone of industrial efficiency, delivering significant energy cost savings while optimizing system performance. By effectively removing condensate and non-condensable gases without losing valuable steam, steam traps ensure your operations run smoothly and sustainably.

Their ability to prevent equipment damage, reduce downtime, and enhance heat transfer directly translates into lower energy bills and increased productivity. Whether you choose thermodynamic, thermostatic, or mechanical designs, each steam trap type addresses specific needs, offering flexibility across applications.

Yarway steam traps, available through Proconex, elevate this efficiency further with reliable, industry-leading solutions tailored to diverse demands, from high-pressure systems to sanitary processes. Real-world results, like the Gulf Coast chemical plant cutting downtime in half, underscore the tangible benefits of pairing steam traps with proactive maintenance strategies.

You gain not only immediate savings but also long-term operational resilience, protecting your bottom line against rising energy costs and unexpected failures. The steam trap function is simple yet powerful, relying on precise mechanics to maintain system integrity; this makes them an investment that pays off quickly.

As industries face growing pressure to optimize resources, steam traps stand out as a proven tool to achieve that goal. With Proconex’s expertise and a robust selection of steam trap valves, you can implement these solutions seamlessly, ensuring your facility operates at peak efficiency while keeping energy expenses in check. Embracing steam traps means embracing smarter, more cost-effective operations. Contact us today to discuss your needs!