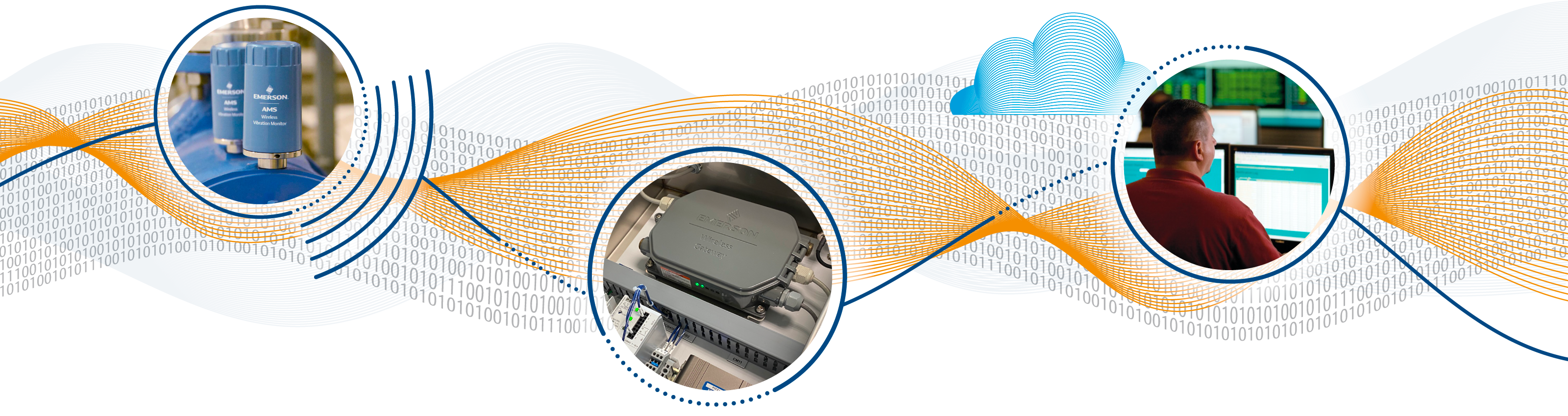

Keep Critical Equipment Running Smoothly, Automatically

Forget clipboard checks and tedious inspections. Our wireless Remote Asset Monitoring solutions help you catch issues early, even in hard-to-reach areas. With easy deployment and no IT headaches, you’ll reduce downtime, cut costs, and keep your plant running reliably, automatically.