In process automation, staying ahead with the latest technologies is a necessity.

For plant managers aiming to ensure their operations remain competitive, reliable, and scalable, PLC (Programmable Logic Controller) modernization stands out as a pivotal strategy to future-proof their plant. Proconex, leveraging over 75 years of expertise in process control systems in the Mid-Atlantic region, emerges as your premier partner in this transformative journey.

Why Modernize Your PLCs?

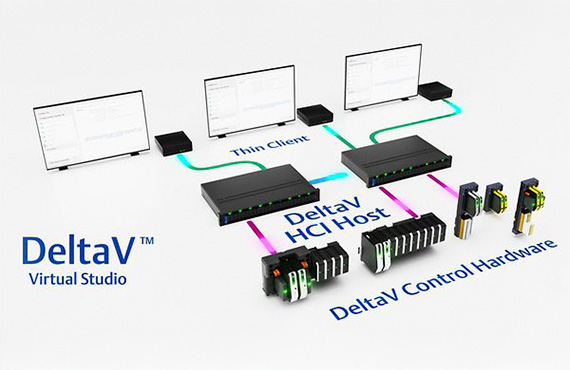

The transition from legacy systems, such as the widely utilized Allen-Bradley PLC-5, to more advanced solutions like the Emerson DeltaV PK Flex Controller is crucial for several reasons. Firstly, the obsolescence of legacy PLCs means dwindling factory support, posing significant risks to continuous process control and data management. Furthermore, the maintenance of outdated equipment and software requires additional databases, skillsets, and spare inventories, complicating operational processes and inflating costs.

Choosing Proconex for Your Modernization Needs

As the exclusive Emerson Impact Partner for Emerson Automation Solutions in the Mid-Atlantic region, Proconex is in a unique to address these challenges. Our comprehensive portfolio of Process Automation Control Systems, Valves and Control Devices, coupled with cutting-edge software and services, ensures a seamless and efficient modernization experience. Catering to a diverse client base across Life Sciences, Chemical, Power & Energy, Refining & Upgrading, Oil & Gas, Food & Beverage, Pulp & Paper, Metal & Glass industries, and more, we tailor our solutions to meet and exceed your specific operational requirements.

Benefits of partnering with Proconex

- Expertise and Experience: With a legacy spanning over seven decades and a deeply committed team of over 200 professionals, Proconex brings unmatched expertise and practical experience to your PLC modernization project.

- Customized Solutions: Understanding that no two operations are alike, Proconex offers tailored solutions designed to align with your plant's unique needs, budget constraints, and future growth plans.

- Emerson Automation Solutions: As an Emerson Impact Partner, Proconex provides access to a broad array of Emerson’s cutting-edge automation solutions, ensuring your plant benefits from the latest advances in automation technology.

- Safety and Quality: Our unwavering commitment to safety and quality underpins every project we undertake, guaranteeing not only the success of your PLC modernization project but also the welfare of your employees and the integrity of your plant operations.

- Strategic Locations: With three strategically located offices in the Mid-Atlantic region, Proconex guarantees prompt and efficient service delivery, ensuring minimal downtime and interference with your day-to-day operations.

Underrated Tips for Future-Proofing Your Operations with Proconex PLC Modernization Solutions

- Leverage the Power of Data Analytics

Modern PLC systems offer advanced capabilities for data collection and analysis. By partnering with Proconex, plant managers can utilize this feature to predict equipment failures, optimize maintenance schedules, and improve overall operational efficiency.

Tip: Look beyond immediate automation requirements and consider how data analytics can drive strategic decision-making. - Opt for a Phased Integration Approach

Instead of overhauling your entire system at once, consider a phased approach to PLC modernization. Proconex can help identify critical areas that need immediate attention and plan subsequent upgrades that align with budget constraints and production schedules.

Tip: A phased approach reduces downtime and spreads out the financial impact. - Emphasize Cybersecurity from the Start

Modern PLC systems are more connected, which increases their vulnerability to cyber threats. Ensure cybersecurity measures are an integral part of your modernization project. Proconex can guide you in implementing robust security practices.

Tip: Consider cybersecurity not just as an add-on but as a foundational component of your PLC system. - Focus on Training and Capability Building

The success of PLC modernization is not just about technology—it's also about people. Invest in training programs for your team to get up to speed with the new systems. Proconex offers customized training solutions that can be tailored to your operational needs.

Tip: Make training a continuous process to keep your team updated with the latest advancements in PLC technology. - Utilize Remote Monitoring and Management Services

Modern PLC systems supported by Proconex offer options for remote monitoring and management. This can significantly reduce response times to issues and improve uptime.

Tip: Establish protocols for remote operation and consider how remote capabilities can enhance your current operational processes. - Engage in a Comprehensive Asset Management Plan

Work with Proconex to develop a comprehensive asset management plan that includes your new PLC systems. This plan should cover lifecycle management, spare parts inventory, and a clear upgrade path for the future.

Tip: A well-defined asset management plan ensures your modernization efforts deliver long-term value. - Foster a Culture of Continuous Improvement

Lastly, PLC modernization with Proconex should be seen as the beginning of a journey towards operational excellence. Encourage a culture of continuous improvement by regularly reviewing system performances and identifying areas for further enhancements.

Tip: Use the insights gained from data analytics as a benchmark for continuous process improvements.

Embark on Your Modernization Journey with Proconex

Embracing PLC modernization is more than an upgrade—it's a critical step towards securing the future of your operations in an increasingly competitive landscape. With Proconex, you’re not just adopting new technology; you’re engaging a partner dedicated to maximizing your plant’s potential.

Join a growing number of satisfied customers who have future-proofed their operations with Proconex. Contact us today to discover how we can facilitate a seamless transition to modern, efficient, and scalable process automation solutions tailored to your specific needs. Together, let’s ensure your operations are poised for success now and in the future.

FAQs on Proconex PLC Modernization Services

PLC modernization is important for several reasons. It addresses the obsolescence of legacy PLCs, such as the Allen-Bradley PLC-5, ensuring continuity in process control and data management. Modernization also simplifies operational processes, reduces maintenance costs, and leverages new technologies for improved efficiency and competitiveness.

Proconex is uniquely positioned to support your PLC modernization needs with its extensive experience, partnership with Emerson Automation Solutions, and dedication to safety and quality. They offer customized solutions tailored to your operation's unique requirements and ensure minimal downtime with their strategic locations in the Mid-Atlantic region.

Partnering with Proconex offers several benefits, including access to extensive expertise and experience, customized solutions that cater to your specific needs, state-of-the-art Emerson automation technologies, a commitment to safety and quality, and efficient service delivery through strategically located offices.

Yes, Proconex caters to a diverse range of industries including Life Sciences, Chemical, Power, Refining, Oil & Gas, Food & Beverage, Paper, Metals, and more. They offer solutions designed to meet and exceed the operational requirements of their clients, regardless of the industry.

Proconex ensures the success of your PLC modernization project through their deep commitment to safety and quality, leveraging over 70 years of expertise, and offering customized solutions. They employ a team of over 200 dedicated professionals and utilize cutting-edge Emerson Automation Solutions to enhance your plant's efficiency and scalability.

To begin your PLC modernization journey with Proconex, you can contact them directly to discuss your specific needs. They will work with you to tailor a modernization solution that aligns with your plant’s requirements, budget, and future growth plans, ensuring a seamless transition to modern, efficient automation solutions.