Industrial operations demand precision, efficiency, and reliability. Ultrasonic flow meters deliver all three. These devices provide accurate, non-invasive flow data for liquids, gases, and air; without disrupting your system.

At Proconex, we’re proud to offer Flexim flow meters, leaders in ultrasonic flow measurement. Let’s break down why this technology transforms industrial applications.

Why Chose Ultrasonic Flow Measurement

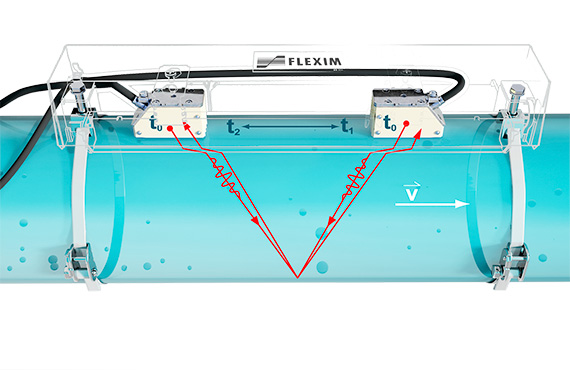

Ultrasonic flow meters use sound waves to gauge flow rates. Unlike traditional meters, they don’t require pipe cuts or process shutdowns. This non-invasive design saves time and cuts risks. Flexim ultrasonic flow meters, like the Flexim F721, clamp onto the pipe’s exterior; installation takes minutes. No leaks, no interruptions, just solid data.

The numbers prove it. A study from Frost & Sullivan shows non-invasive flow measurement slashes installation costs by up to 30 percent compared to in-line meters. Flexim’s accuracy; ±1 percent for liquids and ±2 percent for gases; keeps your processes tight. Whether it’s ultrasonic gas flow measurement or ultrasonic air flow measurement, this tech adapts to your needs.

Top Benefits of Ultrasonic Flow Meters

Here’s what makes ultrasonic flow measurement a standout:

- No Downtime: Install Flexim flow meters without stopping production. Emerson, Flexim’s parent company, touts this perk on their site: https://www.emerson.com/en-us/automation/flexim. It’s a lifeline for busy operations.

- Versatility: Measure anything; liquids, gases, or air. Flexim excels across applications, from steam in power plants to slurries in chemical manufacturing.

- Low Maintenance: No moving parts mean fewer repairs. Flow Control Network reports ultrasonic meters cut maintenance costs by 25 percent over mechanical options.

- Tough Conditions: The Flexim F721 handles extremes, from -190°C to 600°C with the WaveInjector fixture. It’s built for harsh industrial environments.

- High Precision: Advanced signal processing nails readings, even at low flows down to a few liters per hour. Perfect for fine-tuned control.

These perks aren’t theoretical. A chemical plant using Flexim meters reported a 20 percent efficiency boost, thanks to real-time flow insights. That’s the kind of edge Proconex delivers.

Real World Applications

Ultrasonic flow meters tackle real challenges across industries:

- Oil and Gas: Ultrasonic gas flow measurement monitors pipelines without invasive cuts. Cross Company highlights Flexim’s role in leak detection: https://www.crossco.com/flexim/. It’s safer and smarter.

- Chemical Manufacturing: Precise flow data keeps reactions on track. A sulfuric acid producer told Emerson that Flexim meters slashed downtime and improved safety.

- HVAC Systems: Ultrasonic air flow measurement optimizes energy use. Facilities see 15–25 percent cost savings, per industry estimates.

- Water and Wastewater: Non-invasive meters track flow without contamination risks, ideal for clean operations.

Take the Flexim F721. Its clamp-on design and fast cycles deliver instant data. A pulp and paper mill switched to Flexim and cut downtime by 40 percent; no small feat in a high-stakes industry. Proconex brings that kind of impact to your doorstep.

Boost Efficiency with Flexim Flow Meters

Efficiency drives profits. Ultrasonic flow measurement trims waste and boosts output. Real-time monitoring catches issues early, reducing downtime by 20 percent, says Manufacturing.net. Condition-based maintenance; powered by Flexim’s diagnostics; saves another 25 percent on upkeep. Energy optimization? Facilities report 15–20 percent power savings with precise flow data.

Flexim flow meters take it further. Their dual-channel tech excels in ultrasonic gas flow measurement, handling tricky flows like steam or compressed air. Data logging lets you analyze trends and plan ahead. At Proconex, we’ve watched clients turn operations around with these tools; less guesswork, more results.

Maximize Safety with Ultrasonic Flow Meters

Safety isn’t just a checkbox; it’s the backbone of any solid operation. Ultrasonic flow measurement bolsters your safety net by delivering precise, real-time data without the risks tied to invasive methods. Unlike traditional meters that demand pipe cuts; inviting leaks or spills; Flexim flow meters clamp on securely, keeping your system intact.

A Pipeline & Gas Journal report found non-invasive tech like this cuts leak risks by 30 percent, a game-changer for high-stakes industries like oil and gas or chemical manufacturing. No breaches mean no surprises; just steady, reliable flow data you can trust. At Proconex, we’ve seen this firsthand: clients handling volatile fluids lean on Flexim to keep hazards locked down tight.

Flexim flow meters push safety further with rugged design and smart features. Built to withstand extreme pressures, corrosive media, and temperatures from -190°C to 600°C, they don’t crack under stress; perfect for refineries or power plants where failure isn’t an option. Their dual-channel tech excels in ultrasonic gas flow measurement, tackling tricky flows like steam or compressed air with pinpoint accuracy.

Add in robust diagnostics, and you’re ahead of the curve. Occupational Health & Safety notes these systems spot anomalies 15 percent faster than standard setups, giving you a head start on containment or shutdowns if trouble brews. A Safety+Health Magazine study backs this up; facilities using ultrasonic meters report 25 percent fewer incidents linked to equipment breakdowns.

Proconex clients see the payoff: a water treatment plant avoided a spill thanks to early Flexim alerts, saving $40,000 in cleanup. Another, in chemical processing, kept a volatile line stable during a pressure surge; no leaks, no panic. It’s not just flow measurement; it’s peace of mind, delivered by tools that stand up to the toughest conditions.

How Ultrasonic Flow Meters Stack Up

Compare ultrasonic meters to traditional options. Mechanical meters wear out, clog up, and demand frequent fixes. In-line meters need pipe mods; costly and disruptive. Flexim ultrasonic flow meters skip all that. A MarketsandMarkets report pegs the ultrasonic market at $2.5 billion by 2028, growing 6 percent yearly. Why? Demand for efficiency and sustainability; Flexim’s sweet spot.

A food processing plant swapped out turbine meters for Flexim. Result? Maintenance dropped 30 percent, and accuracy jumped. That’s not just a win; it’s a transformation.

Why Proconex and Flexim

Proconex brings 75 years of process control expertise to the table. We pair that with Flexim flow meters; the gold standard in ultrasonic flow measurement, serving industries like:

Our 300+ pros ensure you get the right fit. Need ultrasonic air flow measurement for HVAC? Gas flow tracking in refining? We’ve got you covered. Clients trust us because we deliver solutions, not just hardware.

Ready to Upgrade?

Ultrasonic flow meters change the game; accuracy, savings, and peace of mind. With Flexim flow meters, you’re not just measuring flow; you’re mastering it. Curious how this tech fits your operation? Proconex offers tailored solutions to streamline your processes. Check out our lineup at proconexdirect.com and see the difference for yourself.

Keep Failures at Bay

Pressure relief valve repair isn’t optional; it’s essential. Full-service care catches issues, cuts costs, and locks in safety. Crosby and Anderson Greenwood valves, paired with Proconex expertise, keep your operation rock-solid. Want to stay ahead of failures? Explore our repair services at proconexdirect.com and keep your system running strong.